One-piece fibreglass module.

The Camper module is 3520 x 2150 mm. It is manufactured as a one-piece fibreglass unit. Each composite fibreglass wall and floor component incorporates hi-density foam insulation. The height of the module matches the cab. With the roof in its closed position it is still possible to live inside, during weather extremes or in uncomfortable situations.

Kinetic Mounts - spring packs.

The module is bolted to the chassis at six points with kinetic mounts to absorb flexing

of the vehicle chassis.

Double-action Locks on the Gull Wing Door.

The main access door is a gull wing and provides shade and rain protection for the entrance. With the internal security /fly screen door it provides further ventilation in humid climates. The gull wing door locks are double action locks – the same as in a conventional car door. The side lockers use two compression latchs on each door that when closed compress the pinch weld to a water and dust proof seal.

Looking to the front through the walk-way.

A bellows joins the cab to camper with a duck-through walk-way.

A foot-bridge and two shelves behind the cabin seats cover the bellows, protecting it and giving places to locate small storage boxes.

Pop-top roof and big windows, awning.

Four 12V actuators lift the roof by depressing a switch from either the CAN-bus control panel at the side door or the switch in the living area. The system has a current limiting feature which will stop the roof lift should it be impeded by objects such as a low tree branch.

The vinyl skirt is a high quality block-out and a non see-through material. Three layers including an internal thermal layer reduces the thermal conductivity. Eight large fly screened windows are inset the skirt; they allow for a 360 degree view and good ventilation. The front screen has a full zip for easy access to the cab roof.

Sun screen on RH side and on LH side (pre-awning).

A Thule Omnistor 4900 3x2m wind-out awning, colour-coordinated with the camper is integrated with the roof (see above photo). The winder is kept in the storage area, as are sun screens for the RH side of the camper and for the outer edge of the awning.

In addition to all the drawers and hatches inside the camper, there are two huge storage areas below the bed and accessible from the left and right side externally of the vehicle; the areas are joined, allowing storage of long items.

Modifications

See Side Door Lock, Pop-top Roof, Awning Light, Entry Light, Hatch Light.

Bellows Shelves

Excessive wear of the bellows joining cab to camper has occurred due to rubbing from things left on it. This has led to development of two shelves over the bellows so items can still be sat there behind the cab seats.

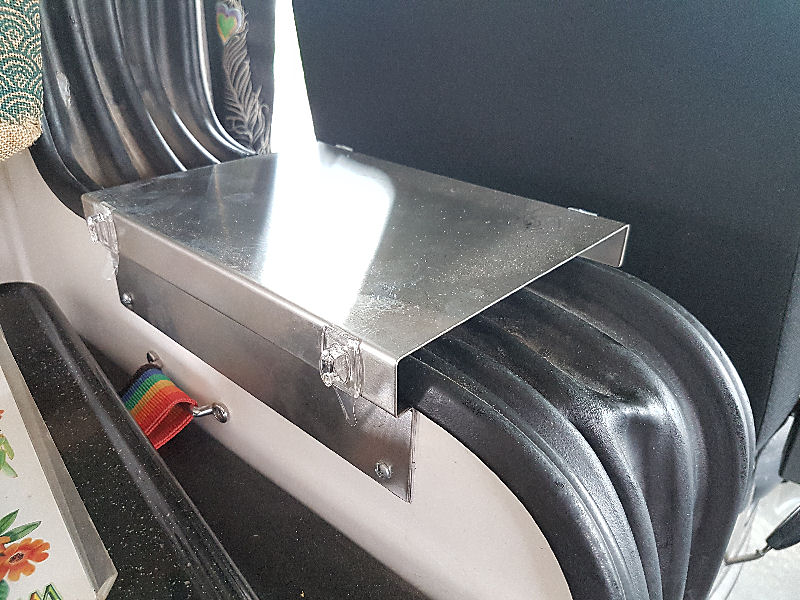

Shelf behind passenger seat. 3M double-sided tape and two screws hold it in position.

Shelf behind driver seat with removable plastic tie-downs. Some repairs to the bellows is evident.

A local sheet metal company bent up the shelves per this drawing.

Cutout Bridge

The foot-bridge between the cab and the camper protects the bellows but makes it difficult to keep the bellows clean. Lots of stuff accumulates there. Being pop-riveted into place, the bridge couldn't be removed easily.

I drilled out the pop rivets and replaced them with M4 aluminium Rivet Nuts. Now M4 cross-point headed bolts hold the bridge in place. Its easy to remove the bolts for cleaning.

Plenty of dirt

Rivet Nut in place

Bridge in place.

Bellows Pinch-weld

The pinch-weld holding the bellows in place rusted away where water pooled outside on the bellows.

The bellows closes the gap between the cutouts in cabin and camper. Its held in place by pinch-welds, a rubber seal with steel grippers that push onto the edges of the cutouts. It took a few years for the steel gripper in the pinch-weld for the cabin to rust out so badly that the bellows sagged and let in water, causing some damage.

I cleaned all the surfaces and glue the rubber seal back in place.

Storage Area Doors

After extensive off-road travels, the storage doors did not seal well. It took a while to realise that the latches are adjustable so that pressure on the pinch-weld could be increased. Each latch has a black roller held in position by a bolt with Allen-key head. One latch on each door has a small round magnet sitting over the bolt head to activate a reed relay to signal that the door is closed. Strangely the size of the Allen key is different for the bolt with the magnet!

LINKS