Engine

The engine is a World Engine, made by Fiat Powertrain Technologies, and used by several companies including Ford, Fuso Canter, and Fiat. It meets Euro 5 emissions standards, using a Diesel Particulate Filter that requires fully synthetic low SAPS (low Sulphated Ash, Phosphorus and Sulfur) oil.

Gearbox

The gearbox is a rugged 6-speed box with change lever on the central console next to the steering wheel. The changes are slow and still stiff after 100,000km of travel.

Gear selection levers for "Half Gear" (green) and Low Range Gear (red).

Transfer Case

The Transfer Case splits the engine torque between front (31%) and rear (69%) axles in All-Wheel Drive mode. A Differential Lock in the Case, selected by a push button on the central panel in the Cab, converts operation to Four-Wheel Drive mode. A Green floor lever engages a synchromeshed "half gear" reduction of 1.3:1, and a Red floor lever engages when stationary a gear reduction of 3:1. So a combination with the gearbox of 24 forward gears, 4 reverse gears with a maximum reduction of 100:1.

The four ranges of 6 gears each are called High, Mid, Low and Extra Low. Normal driving is in High range; low speed, high load 4WD work uses Low range.

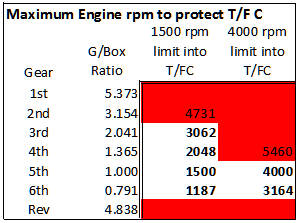

According to the makers of the Transfer Case, inlet maximum speeds to the Case should be limited to 4000 rpm in high range and 1500 rpm in low range, regardless of whether the intermediate gear is used.

A rule of thumb in working up the gears is if I am up to 3rd in Low range, change to High (or Mid) range - this will ensure engine revs and so Transfer Case revs are kept low enough for safe operation.

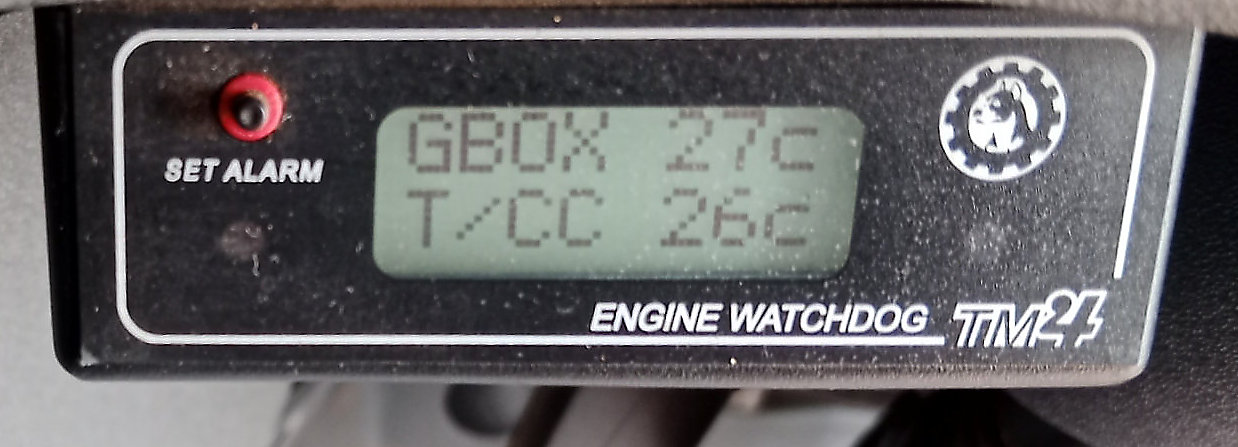

Some users have experienced overheating issues with the Transfer Case, causing the oil to burn. If the specified oil is used the maximum oil service temperature is 120oC. Far better is to use a high service temperature fully synthetic oil: Castrol Syntrax GL5 or equivalent. Additionally, TT30 has WatchDog temperature monitors on the side of the Case, as well as on the gearbox. There have never been any overheating issues for TT30.

Some users have experience catastrophic failure of the Transfer Case when in low range a large O-ring jumps out of a poorly machined groove. A modification made available by Don Incol stops this ever occurring and has been fitted on TT30; there have never been any problems experienced with TT30.

Differentials

Each of Front, Centre and Rear Differentials can be selected for 4WD work or when higher traction is needed (rare, given the great performance of the normal All-Wheel Drive mode). See Four-Wheel Drive mode for how this is done.

Temperature Monitoring

Soon after release, there were several cases of overheating transfer cases on the Daily 55S17W. To monitor TT30 I installed a twin sensor TM4 "Engine Watchdog". There have been no issues. (I do suspect, however that most cases of overheating were occurring because of excessive speed and/or towing heavy loads.)

Transfer case sensor is located below the Transfer Case oil level sight-glass.

Gearbox temperature sensor is set under a bolt low on the Box.

One sensor goes to the case of the gearbox (label GBOX in the monitor), the other goes to the side of the transfer case, below the oil level (label T/CC in the monitor). I bought the default 4m sensor leads; fitment would have been easier with 5m leads.

The wiring diagram is:

and the operating instructions are here for reference.

Because the need to observe the temperature display is infrequent, I have located the display in the footwell of the driver's area. There may be better places, but I have not found them.

Watchdog display after 2 hours running in extremely hot weather.

Watchdog display after 3 hours running in cool weather.

The Watchdog display in the driver's footwell.

Transfer Case

Transfer Case Bushes

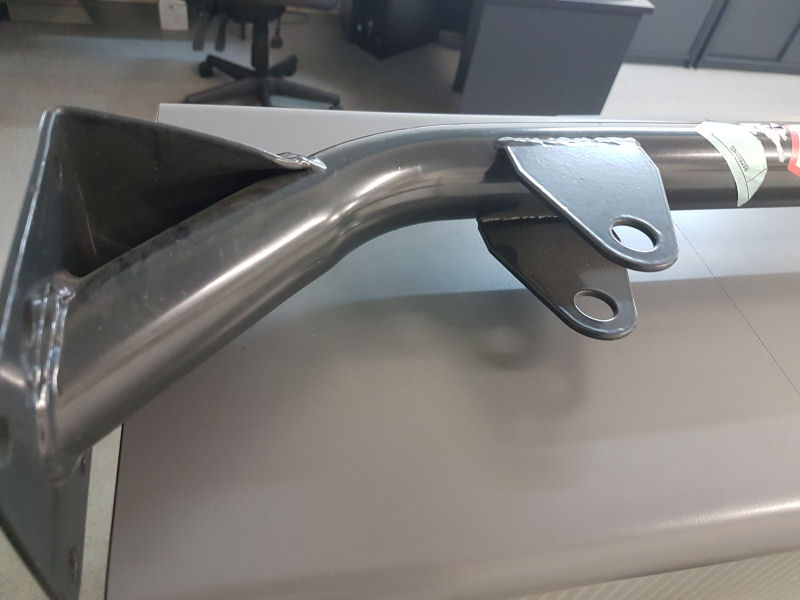

Replacement Poly Bushes for Transfer Case. Inner sleeves but no outer.

The original Iveco bushes used to suspend the transfer case under the truck were a "Silent Bloc" type that was of poor quality. The bushes cracked and so became ineffective in centering the Transfer Case. The result was various clunks and rattles from takeoff, and upon changing gears. TT30 showed these symptoms at around 20,000km. It took Iveco seven years to provide bushes that are fit for purpose. In the interim, amongst other options, TravelTrucks sold a set of Poly Bushes that replaced the OEM bushes and sleeves. These were not so effective at isolating the Case from the vehicle so there was an increase in low level whine. It turns out that the Poly Bushes were indeed far too inflexible and had a large role in a major failure of the cross-member supporting the Transfer Case on TT30.

To remove the outer sleeve of the OEM bush required much force. Iveco garages were either using a sledge hammer and drift (sometimes resulting in broken Transfer Case wings) or dropping the Case and pressing out the originals using a hydraulic press. A far better method was to use a spindle nut pull and press sleeve kit set ("cup and cone") purchased from an eBay seller. This made it possible to apply the necessary force while the Transfer Case was still connected to its drive shafts.

From the kit I used

- the M16 pulling spindle and nuts

- the 44mm dia. Push/Pull Sleeve, turned down to 41.8-mm dia., as the push sleeve, and

- the 60mm dia. Push/Pull Sleeve as the receiving (Pull) sleeve.

I unbolted the Transfer Case and lowered it sufficiently to give access to the OEM sleeves. These were pressed out, the Poly Bushes were lubricated with silicone grease and pressed into position. With the new inner sleeves pushed in, the Transfer Case was raised back into position and bolted in place.

Transfer Case lowered to give access to mounting bushes.

A view of the OEM bushes in the Transfer Case.

Access to the bush on the driver's side is rather cramped.

The rear sleeve halfway out. The 60mm Press Sleeve is on the left, the 41.8mm Push Sleeve is on the right.

The LH side sleeve being pressed out. Looking from below.

A Poly Bush is pressed in the rear mount by an M16 spindle nut and large washer.

Some observations

- Axle stands for the front axle are necessary to stop any rolling.

- The M16 bolt holding the rear bush is shorter than the other two and these latter have a washer below the bolt head.

- 24 mm AF but 15/16" AF spanners are a good fit for the M16 bolts and nuts.

- The handbrake cable needs to be unbolted at the rear lever.

- Two electrical connectors to the Transfer Case needed to be undone.

- The Press Sleeve Kit is of high quality - the spindles are fine threaded and the nuts have ball-race washers to transfer maximum torque. A lot of torque is required to start the sleeve removal - it gives way with a "pop".

- The shiny end of each Poly Bush and the mount holes should be well lubricated with silicone grease.

- A Poly Bush does deform as it is pressed into the mount hole. It is surprising how the end lip compresses and pops back into position when the bush is fully home.

- Install the inner sleeve after the Poly Bush has been fully inserted.

- The handbrake bracket that fits over the driver's-side bush mount bracket needed to be spread just a little before it would go back into position.

A year later I installed revised bushes from TravelTrucks. There had been some reports of broken brackets. The revised bushes had a much thicker crush tube, so now they could not be installed too tightly.

Six months further on and the drive-train did not feel right — a roughness during acceleration and other symptoms. Looking at the Transfer Case mounts I noticed that the left side brackets on the cross-member were both broken and the transfer case was suspended on the fuel tank! The photo shows that the brackets had broken below the welds, presumably due to fatigue cracking. Even the revised TravelTrucks bushings were too inflexible, transferring too much vibration to the brackets. Fortunately the repair was accepted as a warranty claim. It took an Iveco garage several hours to remove the existing cross-member without first removing the auxiliary fuel tank and to install a new cross-member. Revised Iveco bushings were installed in both upper mount holes on the Transfer Case. They have lasted very well.

Low Range Circlip

I was aware that several Transfer Cases had failed, either because of overheating (high speeds, heavy towing loads) or because, apparently, the large diameter circlip that restrains the low-speed planetary gear cluster in place pops out of a poorly machined groove and lets the gears fall loose in the Case with disasterous results.

The thought of the circlip popping out during or after using low range was very unsettling, especially since the Transfer Case of a Daily in the same batch to reach Australia and owned by a good friend failed in the Victorian High Country. An opportunity arose to have the chap who knows most about the Transfer Case and how to fix the circlip, Don Incoll, do work on mine.

Magnetic drain plug (left) covered in steel whiskers, (right) cleaned up.

First task was to drain the oil; at 53,000 km, this was the first time this has been done. The magnetic plug was covered in steel whiskers but the oil was remarkably clean and a light honey colour.

Don removed the Transfer Case from the truck and set it up in a special jig. He then split the rear part of the Case away, exposing the low-range planetary gear block behind its cover held in place with the large circlip in the upper half of the rear case. The groove for the circlip was fairly deep and it took quite a lot of effort to remove the circlip, suggesting to me that this Case would not have easily failed in use.

Transfer Case S/N 6301579 out of TT30.

Case split apart. Upper rear part contains the low-range planetary gear cluster held in place with the large problematic circlip.

On the bench. Click image to see the circlip ends before chamfering.

It wasn't easy to remove the circlip. It appears that the clip had been expanded by hitting the inner sides in several places.

The rear case was set up in a milling machine.

A flat was milled into the case to take a holding clamp for the circlip, which had both ends chamfered the same way.

The prepared holding clamp. When installed it keeps the circlip fully expanded so it cannot jump out of its groove.

Circlip and clamp in position in the rear Case.

Transfer Case assembled and back in position. Lots of cleaner, sealant and thread locker were used beforehand.

I now have the peace of mind to know the Transfer Case will not fail because the circlip popped out.

LINKS