AWD Mode

The Scrubmaster drives in All-Wheel-Drive Mode by default. All four wheels are driven with a torque split 31% to the front wheels, 69% to the rear wheels. This makes for a very capable system and is almost always all that is ever necessary. For example we did a crossing of the Simpson Desert's 1100 sandhills all in AWD; reduced tyre pressure was all that was necessary.

However, if traction is lost to one or more wheels then no power is delivered to the remaining wheel(s) and the vehicle will not drive. This can happen in wet mud or soft sand.

4WD Mode

There are three versions of 4WD for TT30 that can overcome loss of traction:

- Centre differential lock is engaged by pressing the relevant button on the dash panel. The front and rear wheel pairs will rotate and if one of front or rear wheels loses traction the other axle continues to be driven.

- Add then engaging the rear differential lock; even if one of the rear wheels loses traction, the other continues to drive. Meanwhile the front axle continues to be driven.

- Add then also engaging the front differential lock; now all four wheels are driven and if any one or more loses traction the others continue to be driven. Steering is difficult in this mode.

If all four wheels lose traction then the winch may be the only way to escape. This happened to us in September 2017 on the Birdsville Inside Track on the Warburton Flood Plain. We could see conditions deteriorating and suddenly we were in very slippery grey mud and with all diff locks engaged, all four wheels spun with zero traction.

TT30 middle dashboard. In the main bank of switches, diff lock switches on the left and ABS

lights on the right.

Class 1 switches below.

Using the Differential Locks

- The centre Diff lock must be engaged before the rear diff lock will engage,

- The front diff lock can not be engaged unless the rear diff lock is engaged.

- The centre diff lock can not be engaged at speed, you must slow to below 40kph before the computer will allow centre diff lock,

- The centre diff lock automatically disengages over 80kph

- The rear diff lock will not engage above 20kph, automatically disengages over 40kph

- The front diff lock will not engage above 15kph, automatically disengages over 30kph.

- One beep when the lock engages, two when it disengages.

These requirements are imposed by the system in the OEM 55S17W. They are all features of the replacement computer controller for the differential locks that is in TT30. The replacement is very much faster to engage differential locks and has additional features that may be of interest. Developed by Marcus Tuck and Don Incoll, the features are described here.

Check Light

The Check Light on the right of the switch bank, below the large ABS Light relates to the Auxiliary Power Unit (APU) also known as hydraulic diff lock pump, under the metal cover behind camper battery box.

- Low or leaking hydraulic fluid, the light will flash (it can leak directly into the diff locks) — it has never flashed for us even when fluid level was low. Top up the APU fluid reservoir (under a cover behind the spare wheel) with the same GL5 oil as used in the transfer case.

- A steady light indicates a diff lock ECU failure — likely the relay under driver's seat.

- Code flashing - 2 flashes alternated with 3 second pause - failure in the speed signal.

- The self test protocol also illuminates the Check Light when the truck is started.

Relocating Switches and Lights

All the diff lock switches and lights, including ABS lights, have been relocated to the main switch bank. The OEM cable and connectors are long enough. However the mounting frame in the vicinity of the main switch bank has to be cut away (two locating sockets and a cross member) and the little LED lights in their M8 x 0.75 threaded metal housings have to have their resistor and connector tubes cut so they can be bent to fit in the available space. Neutral-cure silicone sealant keeps them in place.

Middle dash frame. Below the switch sockets a cross member and location sockets have been cut away.

Rear view of modified middle dash panel. The LEDs require major changes to clear the frame.

Front view of modified lower middle dash panel. Diff lock switches are on the left, ABS and CHECK lights are on the right.

AFAM Replacement

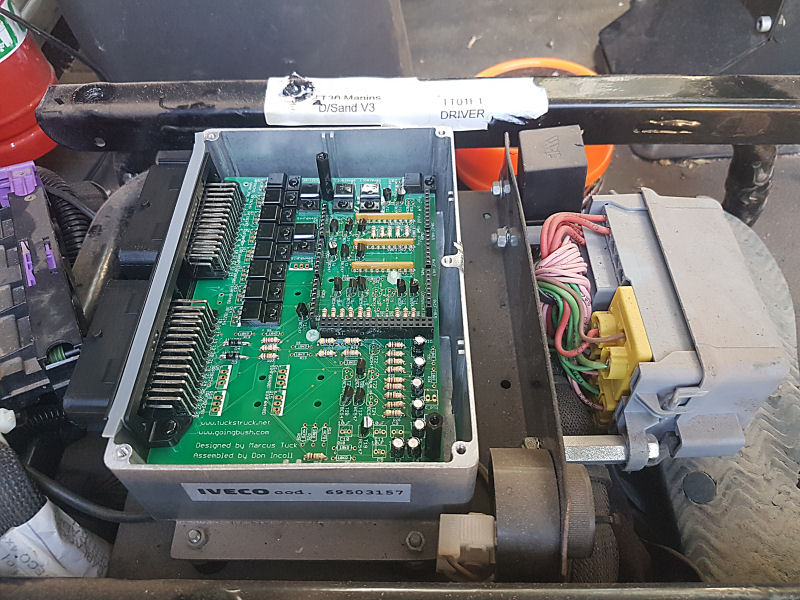

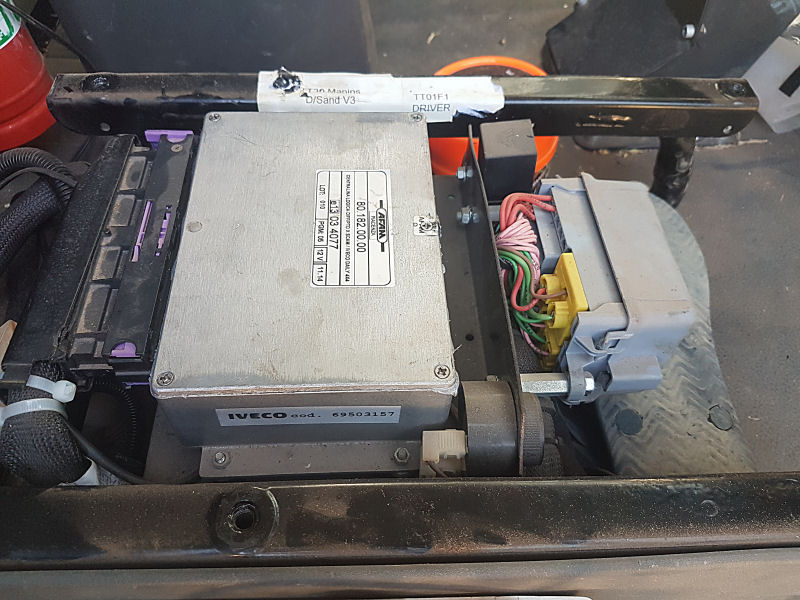

The AFAM is the computer controller for the differential locks. It also turns off the ABS when a lock is initiated. It is located under the driver's seat in a diecast box.

Having experienced lags and failures to engage diff locks when using the OEM AFAM, I bought a replacement from Don Incoll. It has been brilliant, and adds new features as documented.

Now I find diff lock selection much faster, though deselecting Centre Diff Lock can still take an unreasonably long time. A new feature is that a press of the Rear Diff Lock selector switch automatically initiates selection of first the Centre Diff Lock and then the Rear Diff Lock. Or, I can press Centre Diff Lock and then the Rear Diff Lock selectors without waiting for Centre Diff Lock to engage. Another feature is that ABS can be turned off by pressing the Front Diff Lock selector until the small ABS light illuminates. This is an alternative to using the ABS Defeat switch.

Installation

Removing the driver's seat makes access to the AFAM easy.

The new AFAM Computer is a drop-in replacement.

AFAM box lid back on, silicone bead seals the box. Double plug installed.

LINKS