Brakes on Scrubmaster TT30

The brakes on TT30 have been substantially upgraded from the OEM 55S17W brakes. Front brakes have larger rotors, increasing the possible braking force by approximately 25%. And since the rotors are now ventilated, the enhanced ventilation reduces the possibility of brake-fade under heavy use.

Rear brake cylinders have been bored out and new larger pistons fitted. The braking force has been increased by approximately 21%.

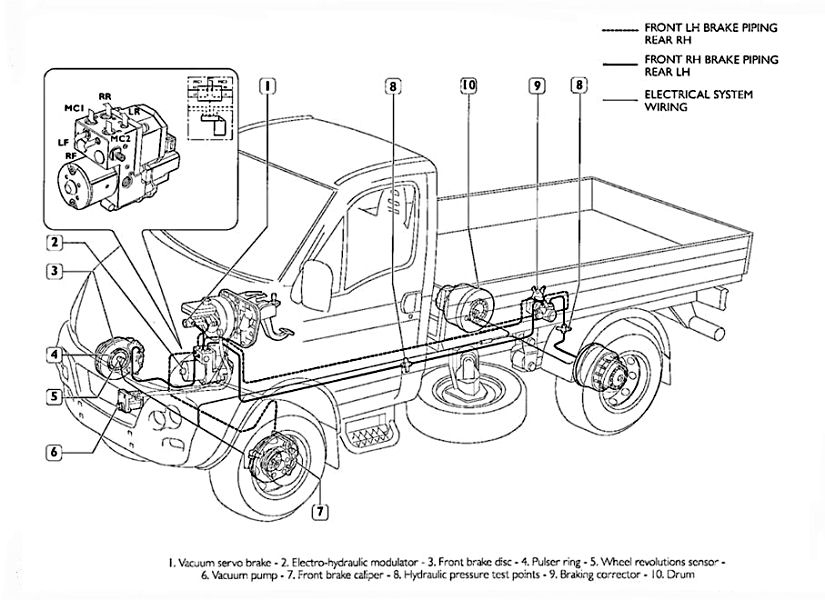

As supplied, the 55S17W came with front-rear split braking: both front brakes being on one circuit and the rears on another. This has been changed to safer and more responsive diagonal split braking: one front and the diagonally opposite rear are on one circuit and the others are on the second.

The upshot is that TT30 has significantly better and safer brakes than Iveco supplied.

Note that replacement front brake pads are 17mm thick, fit the Iveco Daily 35S13 (2002– )vehicles; the more common pads are 19 mm thick.)

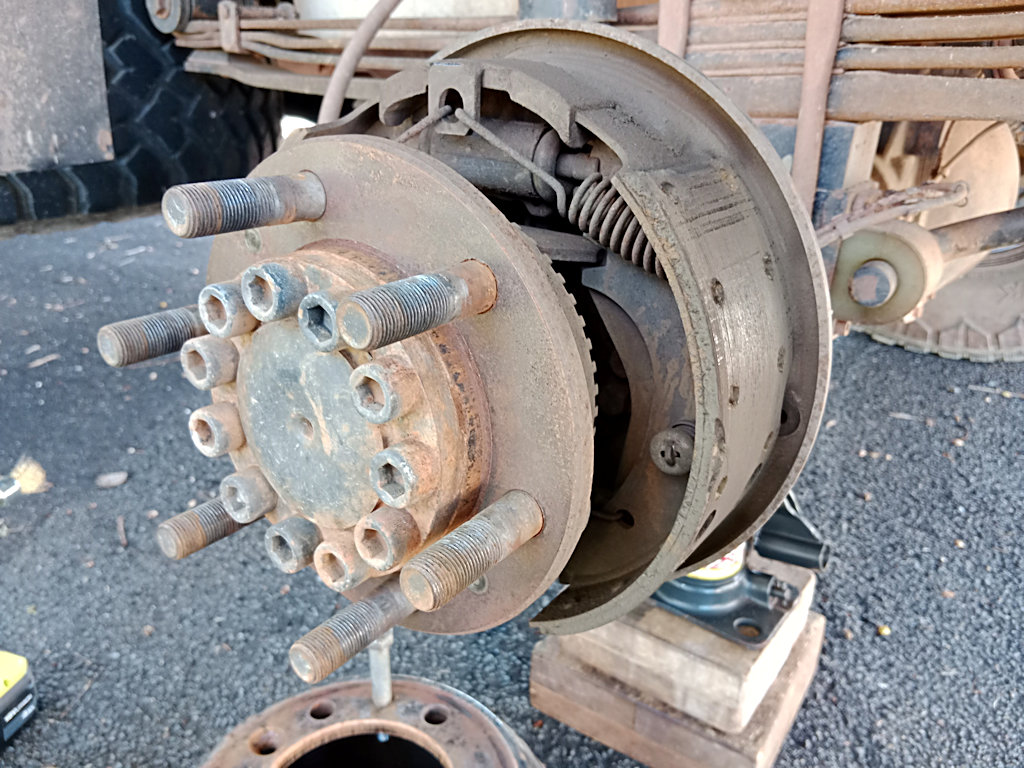

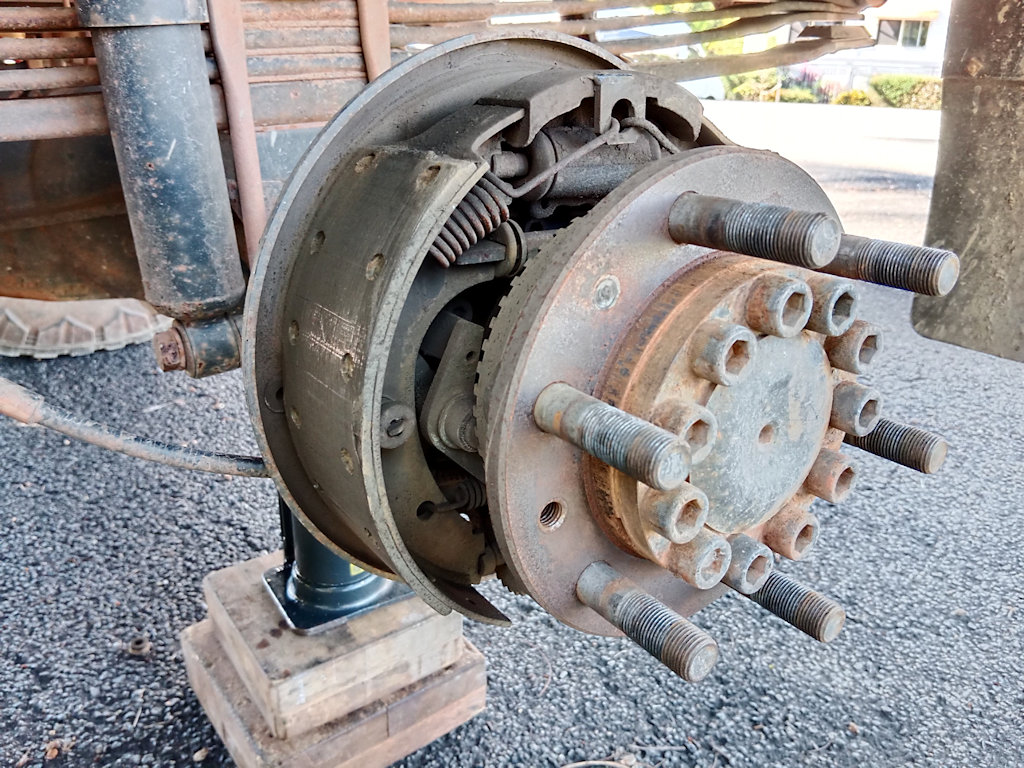

Trailing brake shoe with less wear than the leading shoe.

Leading brake shoe showing rivets well below surface.

Rear Brakes at 134,000 km

The rear brakes are notoriously ineffective. The upside of this is that the shoe linings wear very slowly, which is as well since Iveco charge an obscene amount of money to replace them (go to a brake specialist and get new linings bonded to the shoes).

Here are a couple of pics at 134,000 km of the rear LH brake shoes. The retaining rivets can be seen to be well below the surface of the linings and so have many more kilometres of life.ABS Lights

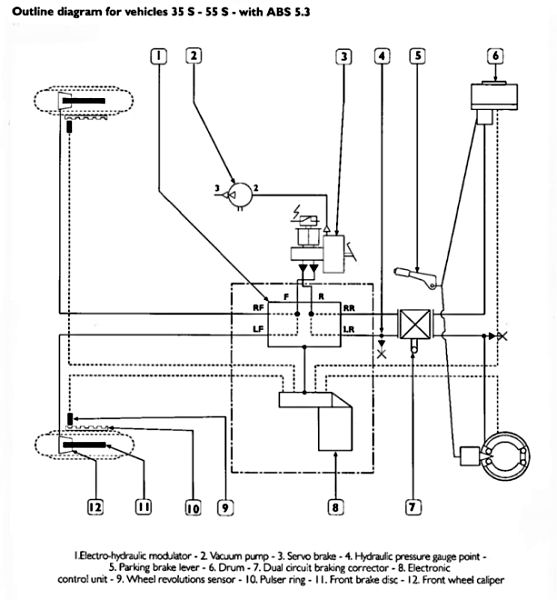

The ABS is a Bosch 5.3 and is fairly basic. It doesn’t have any of the advanced stability controls, only 'anti-blocking'). ABS is automatically switched off when any differential lock is engaged.

The big ABS Light is on the switch bank, above the Check Light. The little ABS light above that lights to tell us when the Differential Lock system has disabled the ABS. So if we have the Differential Lock off (i.e. the small ABS light off) and the big ABS light on, we probably have an ABS fault (but briefly press the ABS-OFF button and see if the fault clears). If we have the Differential Lock on (i.e. the small ABS light on) and the big ABS light on, we have a Lock engaged and we do not have an ABS fault.

ABS Defeat for Off-Road Driving

ABS is switched OFF: small and large ABS lights are ON.

ABS switch OFF. USB port for TPMS. (centre switch unused)

ABS (Anti-lock Braking System) is not very effective in gravel and snow, as it does not let the wheels lock under heavy braking. With no ABS you won't have control of the vehicle, but you will stop more rapidly if you just slam on the anchors. This is because the gravel/snow will pile up in front of the tyres, essentially creating a bow wave which will dissipate more energy than normal ABS braking in those circumstances.

On the Daily 55S17W and TT30 in particular ABS is disengaged when the centre differential lock is selected (this is conventionally called "4WD mode"). However this puts more strain on the transmission and tyres and in any case the torque splitting that is part of normal all-wheel drive ("AWD mode") does a great job. Use the switch next to the steering wheel to turn off ABS in all-wheel drive mode on dirt roads gives the advantages of both.

Discussion

The brakes on the 55S17W were very poor, bordering on unsafe. TT30 does not tow anything, it is not heavily loaded, nor did it run anything other than standard XZY road tyres for the first 23,000km. Complaints to Iveco garages about the brakes were shrugged off, and a letter to Iveco Australia through the Iveco Brisbane office received no response even though one was promised. A follow-up letter a year later to Iveco Brisbane received no response.

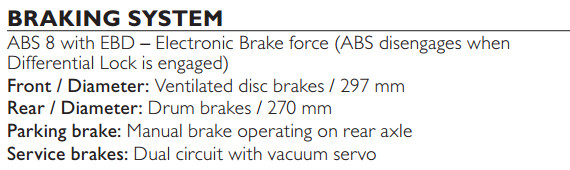

Iveco claimed ventilated disk brakes in front with ABS 8 and EBD systems. Brochure dated July 2012

As supplied the 55S17W had front disk brakes with solid rotors (even though at the time of purchase, Iveco claimed ventilated rotors) and rear drum brakes. Brake force was shared between front and rear using a proportioning valve that is manually adjusted upon delivery according to the expected load. With a camper on the vehicle the load does not change very much and the valve setting is never altered.

Not only did Iveco advertise ventilated disk brakes and ABS 8 and EBD, their submission 061RVD02K dated 18 Jan 2012 to Department of Transport under the Road Vehicle Certification System, CPA 37140-970901, lists the brakes as ventilated disk brakes (DIV) front, disk brakes (DIN) rear. This Certification was in place when TT30 was delivered, February 2015.

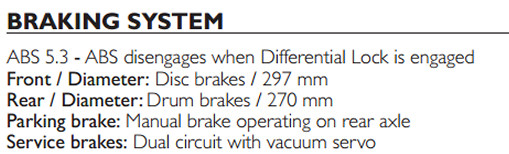

Iveco then claimed solid disk brakes in front with inferior ABS 5.3 and no EBD systems. Brochure dated July 2015.

In July 2015 Iveco put out a revised brochure. As one Iveco salesman said to me soon after, the brochure "has been truthified"! The reality is that all along, the vehicle had solid disk brakes in front (subject too easily to overheating), drum brakes in rear (inferior performance) and a primitive ABS system without EBD.

It took until 17 February 2017 (!) for Iveco to submit a revision 061RVD02Ka listed as CPA 37140-1208661 stating that the brakes were solid disk (DIN) in front and drum brakes (DR) rear.

Note that there is negligible engine braking with the 55S17W due to the way Exhaust Gas Recirculation is set up. There is no exhaust brake.

So we have:

- the non-ventilated brakes on the 55S17W as supplied are dangerous due to poor performance and brake fade and overheating on long descent applications;

- the advertising and marketing of the Daily around the time of purchase was misleading, no, it was a lie;

- the RVCS was untruthful; and

- Iveco Australia knows the factory brakes endanger lives since they have evidently offering selected customers brake upgrades, even for the next model (which has exactly the same brakes as the 55S17W, just smarter electronics).

Additionally:

- Australian Road Rules - Reg 108 requires that "If the driver of a truck [>4.5 tonne] or bus is driving on a length of road to which a trucks and buses low gear sign applies, the driver must drive the truck or bus in a gear that is low enough to limit the speed of the truck or bus without the use of a primary brake." See: here. The Daily 55S17W does not comply. With no engine braking, no retarder, no exhaust brake there is no way the speed of the truck can safely be limited on long steep hills without using the service brakes.

- Australian Design Rules 35/02 requires that in the case of a brake line fail where there is a loss of 75% or more of the brake fluid, a visible indicator must be activated to warn the driver. In the 55S17W there is only a non-compliant indication when ALL fluid is lost.

- Rule 35/02 also requires that the parking brake system must compensate for effects of wear automatically. On the 55S17W only the leading rear brake shoe is adjusted. The trailing shoe DOES NOT adjust automatically.

- The brakes on the 55S17W are split between front and rear instead of a safer diagonal split.

Very poor Iveco! You are treating Australians, and me in particular, as mugs and endangering lives.

Front Brake Upgrade

Vari Racing offer a kit to upgrade the front brakes to larger diameter, ventilated, rotors. In addition to much better brake performace, when it comes time to replace the rotors it will not require a hugely expensive dismantling of the swivel housings — the new rotors simply bolt on and off.

Nevertheless, it was an expensive exercise. The new rotors require that the wheel rims have adequate offset. Mine did not. I had to purchase new rims and the wheels reassembled and installed at TravelTrucks. The new rims are branded Gecko Wheels, have a load rating of 2100kg, and an offset of 41.5mm.

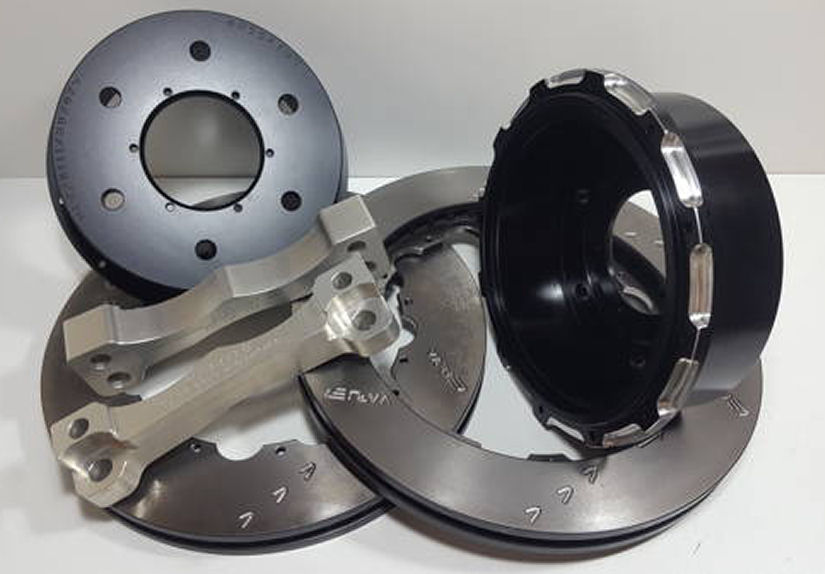

The Vari Racing kit is a two-piece rotor system — slotted rotors of 342mm diameter x 28mm. It makes use of the original Iveco Daily 4x4 caliper and relocates it with a heavy-duty aluminium bracket. The rotor is case-hardened and bolted to a new mounting hub (”Rotor Bell”) which includes air flow features to enhance the advantages of a vented rotor.

Vari Racing did the installation of the brake upgrade and this took a full day at their premises in Gleneagle, SE Qld.

Installation included new wheel bearings and brake pads. Vari Racing say the OEM Iveco pads are good and last well whereas the other branded pads wear quickly. Since the rotors are hardened, rotor wear will not be a big issue.

Cesare is part-way through the disassembly of the RH brake. OEM rotor is non-ventilated, 297 mm dia x 22 mm thick.

Total disassembly is required to access the OEM rotors (as it would be when worn). New wheel bearings required.

Cesare does a trial fit of the new Vari slotted rotor. It is 342mm dia x 28mm, 15% bigger than the Iveco OEM.

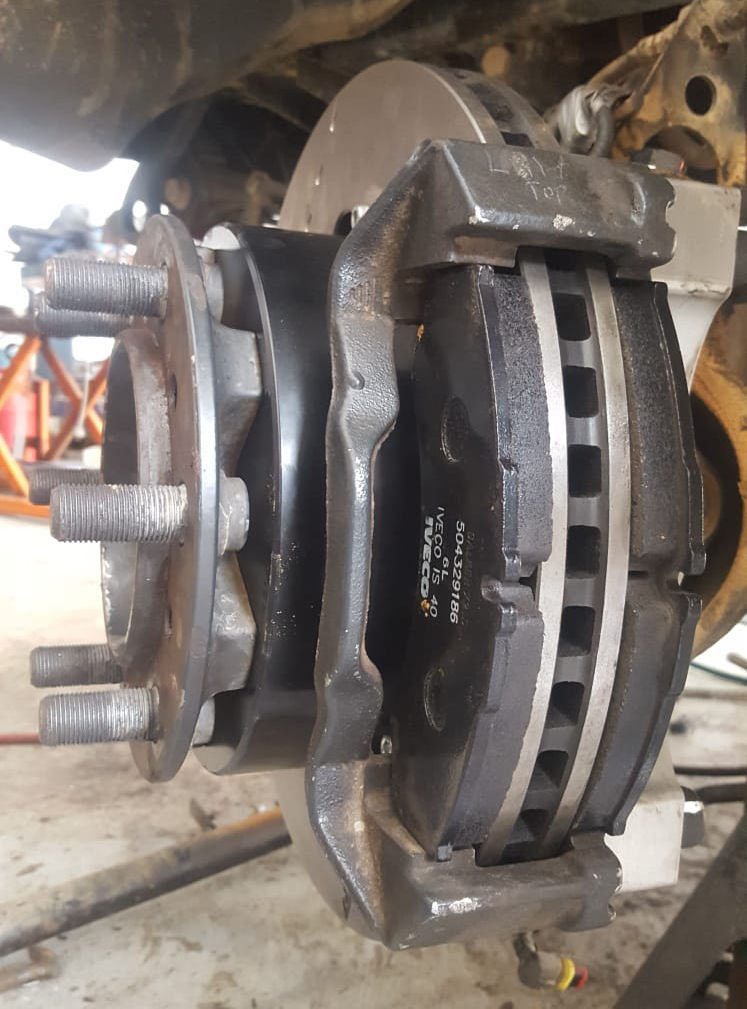

The brake calipers require machining to sit further out than originally.

A caliper that has had the machining done.

A completed installation on RH side: new rotor bell, slotted rotor, pads and caliper location bracket.

The extra rotor diameter increases the possible braking force by approximately 25%. And the enhanced ventilation reduces the possibility of brake-fade under heavy use.

Rear Brake Upgrade

Rusty, wet, rear brake proportioning valve from TT30 before being "fixed" by BHSS.

TravelTrucks had correctly set up the problematic rear brake proportioning valve so that TT30 did have noticeable braking from the rear shoes. However braking was poor and had to be improved. BHSS offers a service to "fix" the proportioning valve so that the rear brakes operate at maximum capability, and to increase the braking force from the actuating pistons by increasing their diameter.

BHSS disassembled the proportioning valve and found it in poor condition, filled with water and rusted up: a failure waiting to happen.

BHSS bored out the rear brake cylinders and pressed in stainless steel sleeves, increasing the diameter from approx. 20mm to 22mm (13/16" to 7/8"). New larger pistons were fitted. Therefore the braking force has been increased by 21%.

A test drive showed a definite improvement in braking performance. ABS would even work upon heavy braking — something that had not happened to that stage. The rear braking performance has improved further over time.

BHSS chap at work on the rear brakes proportioning valve.

Old and new pistons for the rear brake hydraulic cylinder.

Rear brake cylinder assembly in position ready for work.

Conversion to Diagonal Split Brakes

Diagonal split brakes mean that instead of both front brakes being on one circuit and the rears on another, one front and the diagonally opposite rear are on one circuit and the others are on the second. This is arguably safer if a brake line fails, depending on the design and fluid capacity of the dual master cylinder.

Importantly, because of the difference in fluid volume required to activate the front brakes compared with that required to activate the rear brakes, changing to a diagonal split makes the brakes more responsive — less pedal travel for the same brake piston travel. Instead of one of the two master cylinders controlling the four large pistons in the front brakes, it now only has to control two, plus two much smaller pistons in the rear brakes. However, the same pedal pressure as before is required.

As shown in the left diagram, the 55S17W comes with a front-rear split. However, the sketch on the right, taken from the same workshop manual, shows it as a diagonal split. One of very many errors in Iveco documentation.

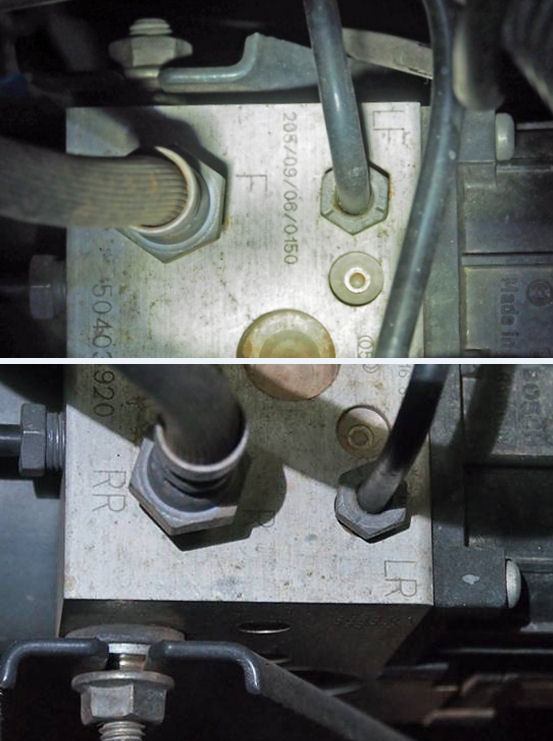

Examination of the top of the ABS "electro-hydraulic modulator" (left) shows it marked out for a front-rear split, not a diagonal split. The rear brake lines go to the front, the front brake lines go to the rear of the block.

Changing to a diagonal split is easy enough: swap the position of the left front (LF) brake line with the left rear (LR). The pipes are long enough to do this. The photo on the right shows the job done.

There is a (small) negative in doing this with the existing dual master cylinder. Since the chambers are not the same size for the two circuits, if a brake failure occurs there will be a different residual braking performance depending on which split fails. Better would be a master cylinder with equal chambers, but we don't have that.

There is one more change. The ABS has to be told of the change otherwise it might release the brake on the wrong wheel in a skid and send the vehicle out of control. The pin assignments for the plug on the side of the ABS unit are shown in this table. We need to swap the wires to pins 6 & 7 (LF) with the wires to pins 8 & 9 (LR), just as we have done for the brake lines.

I disconnected the battery, removed the front inner guard to the left wheel

arch and was then easily able to remove the ABS plug, take off its cover and

locate the white and black wires that needed to be swapped over. It is very

important to be methodical here. Its all too easy to mix up the wires once cut.

Cut one white wire, strip insulation from the end going to the plug, cut the

other white wire and strip insulation from the end going away from the plug.

Slip heatshrink over one wire, solder together and seal the heatshrink.

Repeat for the remaining white wires. Repeat the procedure for the black wires.

The arrow points to the plug on the side of the ABS "electro-hydraulic module".

Cover removed, the wires 6 & 7 need to be swapped with wires 8 & 9.

I could not extract the pins, so had to cut and swap the wires, then solder and cover in heatshrink.

With everything back together, the left brake lines may need bleeding to get any introduced air out. The nipple on the front requires an 11mm spanner; that on the back requires a 7mm spanner. I found that no air had entered the lines; however brake fluid from the master cylinder reservoir had drained out over the ABS unit while the lines were disconnected but that is all. This was hosed off.

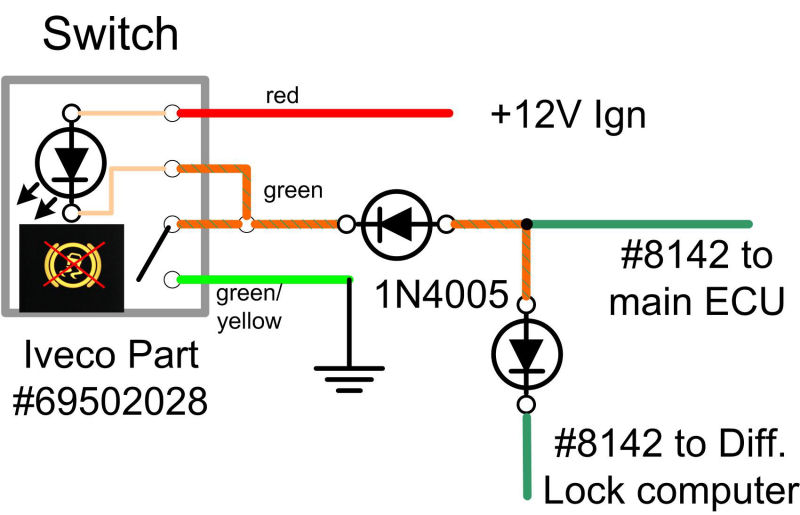

ABS Defeat Switch

As discussed by Marcus Tuck, when the AFAM (differential lock management control unit which is under the driver's seat) wants to turn off the ABS it supplies an earth, on the green wire number 8142, to a particular relay coil behind the dash. By cutting this wire, inserting a protection diode and a switch to earth on the other side of the diode to the AFAM I can turn off ABS at any time. The 'ABS Failure' and 'ABS' lights come on when the ABS is turned off (in the same way as they do when the differential locks are engaged). If the centre differential lock is engaged the AFAM system still turns off the ABS automatically.

I cut wire 8142 at the AFAM double-plug, under the rear of the driver's seat. The wire is labelled 8142 every few centimetres so is not hard to find.

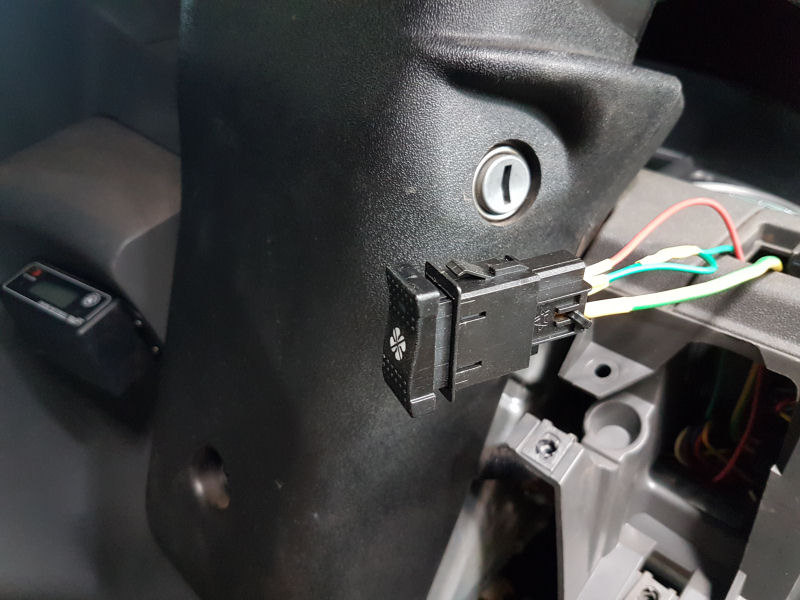

I use an OEM Iveco radiator fan OFF switch, relabelled as ABS-OFF, installed to the right of the steering wheel. It is illuminated whenever the switch is activated (as do the 'ABS Failure' and 'ABS' lights).

Ignition-switched 12V power for the switch LED comes from a repurposed driver's seat heater supply. A (7-core) cable taking the new earth signal and 12V power was run under the floor matting to the chosen location on the dash. A local earth near the switch (on the lower door pillar) completes the circuit.

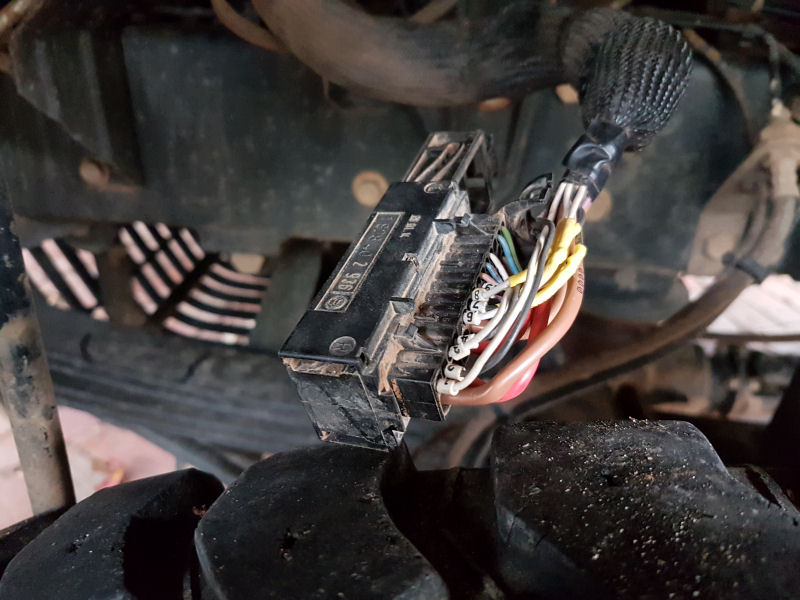

The AFAM double-plug and cut 8142 wire.

Diodes inserted into the 8142 wire and the switched earth signal wire.

Switch with wires installed. The wires are individually plugged using suitable crimped pins and the whole potted with silicone.

LINKS