Bike Rack for the Applause Motorhome

Having bikes with us is very handy — reduces the need to pack and go from a camp, and gives us access to places not otherwise easily reached.

Carrying Bikes - Alternatives

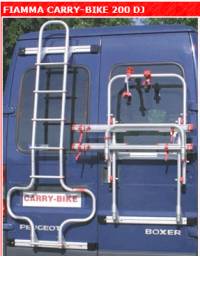

The obvious option is to put a Fiamma Carry-Bike on the back of the Motorhome. There is even a model designed for the Fiat — the Carry- Bike 200 DJ Ducato. It mounts on the rear door on the driver's side.

But this approach has bikes extending across the whole back of the van and makes opening the doors awkward. I also had plans for the other door.

The VW Vanagon bike and general carrier racks of Canadian Gary Lee were inspiration for a different approach: instead of mounting the bikes across the rear doors, I would mount them vertically, down one of the doors, using fittings for holding bikes more often found on the roof of vehicles.

However, the Ducato rear doors are quite high, and so something to take the weight while loading and unloading the bikes appears necessary. The stability of the bikes when on the rack would also benefit.

Australian Road Safety regulations require that the maximum rear overhang of the Ducato, including any load carried (ie, the bikes in this case), is the lesser of 60% of the wheelbase or 3.7 m. Additionally the load must not project more than 1.2 m beyond the rear of the Ducato.

The Ducato wheelbase is 3700 mm and the overhang of the body is 998 mm, so the maximum overhang of the bikes must be no more than min(1200, 60% * 3700 - 998), ie 1200 mm.

My Custom Bike Rack

I made rails out of rectangular box section aluminium and attached these at three heights to the rear door on the driver's side. I use the Rhino-Rack "Claw" to lock the bike front forks to the top rail, and a fold-out "U" shaped aluminium loop on a channel for the bike's rear wheel, to hold that in position.

The top rail is 50 x 25 x 3.0 mm aluminium rectangular tube, with a slot sawn along the length of one wide face to turn it into a lipped channel. The channel is bolted to the rear door above the window using M5 x 75 mm stainless steel countersunk head machine screws at 100 mm spacing. The seven screws thread into a 30 x 5 mm steel backing plate on the inside of the door. I painted (oil based enamel, colour matched at Bunnings) the backing plate the same colour as the Ducato van and is, like the channel, separated from the door metal by a strip of sponge rubber. I applied butyl mastic to the outside sponge rubber strip to seal it against the van door. This stuff can flex a lot as the bikes load and unload without letting dirt and water into any gap.

Aluminium blocks 40 x 10 x 50 mm long were drilled and tapped to take one each of the M6 bolts of the Rhino Claw. These blocks slide in the channel, allowing adjustment for the bikes.

Two rails are used below the rear window to locate the carrier for the bike's rear wheel. The channels are 40 x 25 x 2.5 mm aluminium rectangular tube, slotted on the circular saw along the length. There is some access to the back of the door panel for mounting the upper rail so a piece of wood was glued to the inner door panel to accept the five sheet metal screws that are used to attach it. A hollow-wall anchor is used at each end of the channel, instead of a sheet metal screw. The pic shows a rear view of a hollow-wall anchor in position. Fibre washers were used to separate the anchors and sheet metal screws from the aluminium (to reduce electrolysis) and plenty of Lanolene grease was used during fitting (to reduce rust in the door).

The bottom rail is the same as the middle one, except no reinforcing behind the door panel was deemed necessary.

Each rail has a full length of 2 mm thick sponge rubber contact-cemented to its back to separate dissimilar metals to reduce electrolysis and to provide take-up room for the hollow wall anchors.

The rear wheel of the bike sits in a vertical channel of aluminium 60 x 32 x 3 mm spanning the two lower rails. This channel is wide enough to accept trail bike tyres. The channel is held on the rails in the same manner as that for the claws - the channel is bolted to a 35 x 10 x 50 mm block of aluminium using an M8 countersunk head stainless steel machine screw. The block slides in the rail, allowing adjustment.

A "U" of 20 x 6 mm aluminium was fashioned to loop over the back wheel of the bike and to pivot near the top of the vertical channel. Braces, also from 20 x 6 mm aluminium, are used to hold the "U" out from the channel as necessary. Several location holes in the vertical channel allow for adjustment of where the "U" is positioned, and how far it extends out. The arrangement can fold flat against the channel when there is no bike aboard.

The assembly bolts are either M6 stainless steel with spring washers and nuts or, where it is desirable to have some friction in the pivots, nylon M8 setscrews tapped and pinned (using 1.5 x 16 mm stainless steel wave springpins). M4 stainless steel countersunk head machine screws are used to hold the pivot arms in place, and after cleaning with Acetone, all relevant threads received a dab of Loctite 243.

To load a bike, the "U" is folded out from the back of the door and pinned into place. With the front wheel removed, the bike is lifted so the rear wheel is located in the vertical channel and the weight is taken by the "U". Then the bike is easily pivoted forward and the forks located into the claw, which is then locked in position. The front wheel is set against the bike frame and held there using two Velcro tapes. A bike lock is threaded through the frame, rear wheel and carrier and secured.

LINKS

- A'van http://www.avan.com.au

- Fiamma http://www.fiamma.it/home/home.asp?Lingua=EN

- Rhino-Rack http://www.rhinorack.com.au

Custom Bike Racks

Ready to go: two trail bikes on board. An outboard motor rack for the Porta Bote occupies the other door!

Seven machine screws thread into a backing plate and are used to hold the top channel to the door.

Hollow wall anchors and 5 sheet metal screws hold the lower two channels to the door.

Two bike racks on the rear door - both folded for travel without bikes.

One bike rack folded, the other in use.

One rack ready for bike, the other in use.

A trail bike and a road racer on the back of the Applause.

Two trail bikes on board, with bike locks and red security strap. Porta Bote is on the side and outboard motor and dolly wheels are on the other back door.